RUDDER BEARINGS & SEALS

Tides Marine Rudder Bearings & Seals

Tides Marine is committed to designing and manufacturing marine system components which improve vessel performance and reliability, solve unique marine system issues, reduce the need for scheduled maintenance and provide worry-free, long term boating enjoyment.

Please view our full catalogue of Tides Rudder Bearings and Seals.

Upper Rudder Bearing - STD

The Tides Marine Upper Rudder Bearing-Standard (URBSTD) is designed to be mounted directly on top of the rudder shelf. It is an ABS and Lloyds-approved, self aligning design which accommodates up to 10 degrees of off-axis alignment between the mounting surface (rudder shelf) and the rudder stock. As a result, it requires no shimming during installation and won't load up the rudder shaft during vessel operation. The URB-STD is lighter than conventional bronze units. It consists of a UHMW ball-type bearing captured within an UHMW housing. The ball-type bearing is designed with a shoulder at the top to accept a rudder collar, allowing the unit to effectively carry rudder "download" during vessel operation.

The Tides design eliminates metal-to-metal contact and the associated problems of abrasion, electrolysis and corrosion. The URB-STD is self-lubricating and maintenance free. Steering is smoother and quieter.

Upper Rudder Bearing - LP

The Tides Marine Upper Rudder Bearing-Low Profile (URB-LP) is designed to be installed on vessels where the steering system components need to be located as close to the rudder shelf as possible. Mounted "through" the rudder shelf, this design maintains a clean, low-profile appearance. Like the URB-STD, the URB-LP is an ABS- and Lloyds-approved, self-aligning design which accommodates up to 10 degrees of off axis alignment between the mounting surface (rudder shelf) and the rudder stock. As a result, it requires no shimming during installation and won't load up the rudder shaft during vessel operation.

The URB-LP is lighter than conventional bronze units. It consists of a UHMW ball-type bearing captured within an UHMW housing. The ball-type bearing is designed with a "flat surface" at the top to accept a rudder collar, allowing the unit to effectively carry rudder "download" during vessel operation.

The Tides design eliminates metal-to-metal contact and the associated problems of abrasion, electrolysis and corrosion. The URB-LP is self-lubricating and maintenance free. Steering is smoother and quieter.

Rudder Port System - Tube

Based upon Tides' patented Type D System, the Tides Marine Rudder Port/Bearing Tube System (RPB-Tube System) is another rudder system approach which can be used effectively by FRP boat builders. These tube systems are installed during initial lay-up, providing the builder with an accurate, repeatable way to position the rudder bearing and sealing function in their vessels time after time.

An upper and lower bearing machined from UHMW are aligned and assembled into an FRP tube (constructed using either epoxy or vinylester resin). Two lip seals system overview are contained in the top of the tube. With minor mold modifications, the Tube System can save boat builders several hours of post-lay-up installation time. Tube System options are available for a variety of hull configurations and installation training is available for all builders.

Rudder Port Bearing - Type C

The Tides Marine Type-C Rudder Port is used in vessels constructed of FRP, steel or aluminum which have an integral rudder port tube and flange. Unlike the typical assembly with separate bearing and packing, the Type-C unit combines both sealing and bearing functions in a cost-effective housing. It is an ABS- and Lloyds-approved design and offers a substantial "bearing surface" to "rudder stock diameter" ratio.

The units consist of a one-piece UHMW housing and a nitrile lip seal. The Type-C is 100% watertight. It eliminates metal-to-metal contact and the associated problems of abrasion, electrolysis and corrosion. Rudder chatter and vibration are reduced resulting in quieter, smoother performance.

Rudder Port Bearing - Type D

The Tides Marine Type-D Rudder Port System is an integrated approach to rudder port design and installation developed for the FRP boat builder. Unlike conventional post-lay-up rudder port installations, the Type-D system components are built into the hull at the time of lay-up resulting in a stronger, better performing port and bearing assembly.

One reason many boat builders are changing to the Type-D system is the significant labor savings associated with this approach. To accommodate various conventional rudder ports currently available, builders have to perform a variety of post-lay-up operations on each hull being produced. These include: building up / leveling mounting blocks, locating the correct position and axis for the rudder stock hole, aligning and drilling pilot holes and subsequent thru-holes, checking and adjusting for misalignment which may have occurred along the way and, finally, locating and drilling the mounting holes for the conventional port unit. These operations require special jigs and fixtures, several skilled workers, numerous tools and significant man hours to complete.

The Type-D Rudder Port System incorporates a unique FRP liner into each hull lay-up which accepts a matching rudder bearing and lip seal assembly. The placement and angle of each liner is predetermined by a one-time mould modification. From that point on, every hull made from this mold will have an identical, perfectly-aligned rudder port and sealing assembly. Post-lay-up operations once requiring hours of skilled labor are eliminated

Rudder Port Bearing - Type E/F

Tides Marine RPB Type-E and RPB Type-F units are designed to be installed in rudder tubes which have been glassed or welded into a vessel's hull. Type-E units have a flange and Type-F units do not. They may be used on power boats and sailboats. To improve the strength of the bond between these units and the rudder tube, external bonding grooves are machined into the OD of each part.

The units consist of a one-piece UHMW housing with a nitrile lip seal. They eliminate metal-to-metal contact and the associated problems of abrasion, electrolysis and corrosion. They are 100% watertight and eliminate chatter and vibration resulting in quieter, smoother operation.

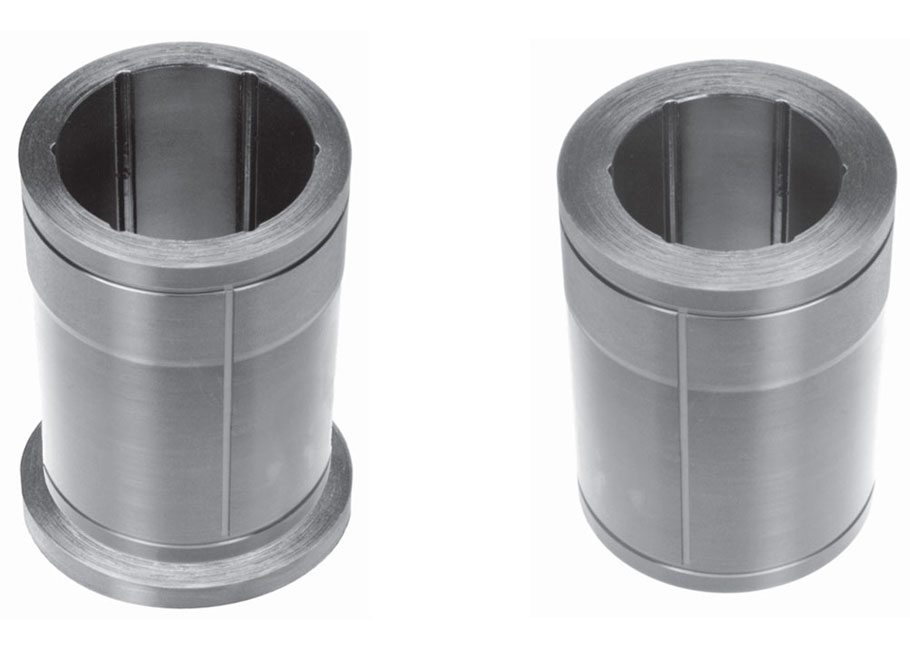

Rudder Port Bearing - Type G/H

Tides Marine RPB Type-G and RPB Type-H units are designed to be installed in rudder tubes which have been glassed or welded into a vessel's hull. These units are simple bearings and do not provide a sealing function.

Type-G units have a flange and Type-H units do not. They may be used on power boats and sailboats. To improve the strength of the bond between these units and the rudder tube, external bonding grooves are machined into the OD of each part.

The units consist of a one-piece UHMW housing which has fluted, self-cleaning grooves running axially along the ID of each part. They eliminate metal-to-metal contact and the associated problems of abrasion, electrolysis and corrosion. They eliminate chatter and vibration resulting in quieter, smoother operation.

Rudder Seal - Type I

Tides Marine Type-I Rudder Seals are retrofit units which are designed to replace hose mounted rudder stuffing boxes. They are connected to the existing bronze rudder port with a flexible hose which aligns the unit with the rudder stock. The assembly consists of a one-piece UHMW housing and a nitrile lip seal. The Type-I will slightly increase the overall height of the rudder port assembly.

These 100% watertight units provide quieter, smoother operation. A pre-cut length of soft-wall hose (purchased separately) must be used with each Type-I Rudder Seal for warranty coverage to apply.

Rudder Seal - Type J

Tides Marine RPB Type-J Rudder Seals are designed to replace the flax packing and compression nut of existing bronze rudder ports. Consisting of a one-piece UHMW housing with a nitrile lip seal, the Type-J is 100% watertight. It is not subject to corrosion or electrolysis and provides quieter, smoother rudder system operation than the bronze stuffing box alternative.

Rudder Port Bearing - Type K

The Tides Marine RPB Type-K was designed to be used with certain flanged, bronze rudder ports with two mounting studs to accept/adjust the flax packing collar.

These units mount directly over the existing studs and are available with or without a lower bearing insert. This insert installs from outside the hull and usually replaces a conventional marine cutless bearing.

The Type-K unit consists of a one-piece UHMW housing with a nitrile lip seal. The unit eliminates metal-on metal contact and the associated problems of abrasion, electrolysis and corrosion. They are 100% watertight and reduce rudder chatter and vibration resulting in quieter, smoother rudder system performance.

Rudder Collars

Tides Marine Rudder Collars are for use on power boats. Machined from 304 stainless steel, each unit comes with two threaded locking screws. A third "indexed hole" (which is not threaded) is machined into each Rudder Collar and may be used as a guide to drill "dimples" in the rudder stock. Simply measure your rudder stock diameter (.000") and select the matching part number from the PDF Specification.

Rudder Spare Seal Carrier Kits

Tides Marine Spare Seal Carriers - Rudder were developed as a convenient place to store spare lip seals on the rudder stock. The unit also makes the job of replacing the lip seal in a Tides Marine rudder port easier and is recommended as an accessory for all Tides Marine rudder ports. Installed at the same time as the RPB, they allow the lip seal to be replaced without uncoupling the rudder stock from the steering system or dropping the rudder.

The unit is a lightweight, two-piece, filled-nylon housing which is affixed to the rudder stock between the Tides RPB and the upper rudder bearing. Each unit comes with a lip seal and red installation hat.